Cement makers have long been criticised for being heavy industrial polluters, but now a consortium of international firms is building a new kind of plant in Belgium which they say could capture more than 95% of CO2 emissions from lime and cement manufacturing.

This new “direct separation” technology adds potentially no additional energy costs and can slash the environmental impact of an industry that is responsible for 5% of global carbon emissions, participants in the pilot claim.

Part-funded by the European Union (EU), the plant will be built at the HeidelbergCement site in Lixhe, Belgium once necessary permits have been secured, and will then undergo two years of extensive testing.

The project is being led by an industry grouping called the Low Emissions Intensity Lime and Cement consortium (LEILAC), which includes HeidelbergCement of Germany, Mexico’s Cemex, UK materials firm Tarmac and Calix, an Australian mineral-processing and carbon capture technology company.

LEILAC was set up to exploit carbon capture technology developed by Calix, which may enable Europe’s cement and lime industries to slash their carbon emissions without significantly increasing their costs.

The consortium says carbon capture will need to be applied to most European cement plants if the EU is to meet its 80% emissions reductions targets by 2050.

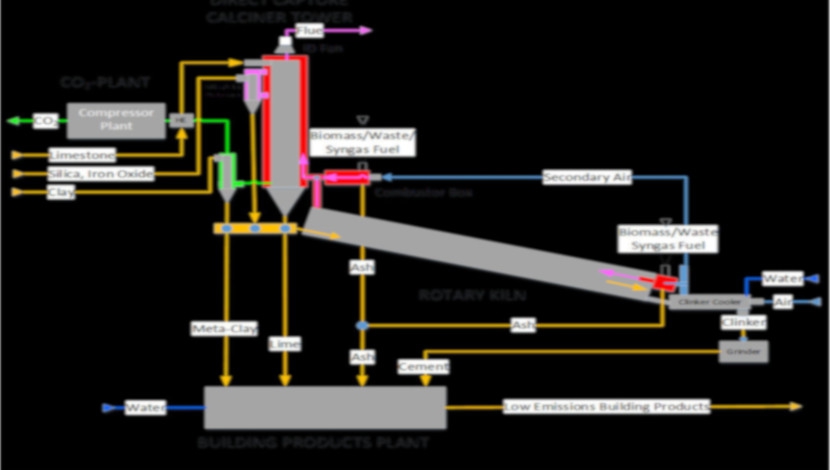

The process flow in Calix’s Direct Separation Calciner

Phil Hodgson, the chief executive of Calix, commented in the company’s newsletter: “Around 60% of the total carbon dioxide emissions from cement and lime plants are released directly, and unavoidably, from the chemical reaction in the production process.

The high-temperature Direct Separation Calciner pilot unit will undergo two years of testing at a feed rate capacity of 240 tonnes a day of cement raw meal and 200 tonnes a day of ground limestone, Calix said.

The process will be studied to see if the technology can be scaled up. The project results will be shared with industry at intervals during the testing.

Other members of LEILAC are Belgian limestone producer Lhoist, UK engineer Amec Foster Wheeler, the Energy Research Centre of the Netherlands, Imperial College London, Spain’s PSE Cement Trading, Swiss environmental consultant Quantis and the UK’s Carbon Trust.