30% Savings on Materials Easily Achievable

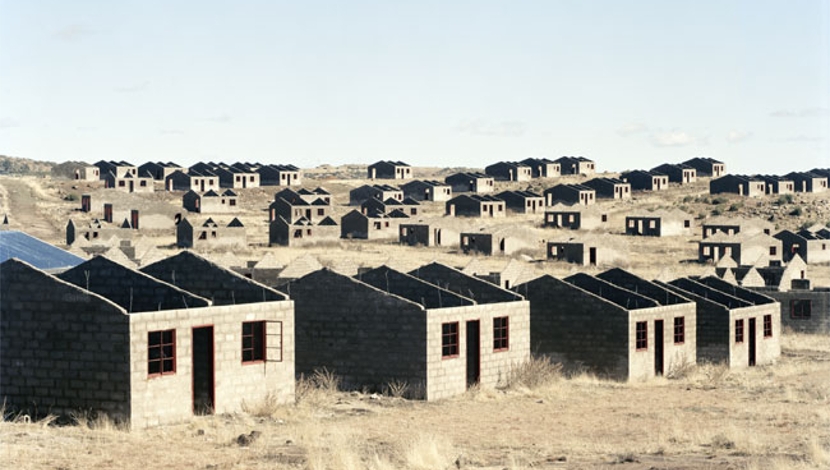

While in-roads into the supply of affordable housing in South Africa have been made, there is still a long way to go in the delivery of the quantity of housing required for the vast amount of people in need across the country. This, coupled with the requirement to be cost effective in the current economic downturn, is where prefabricated walls, floors, frames and foundations can offer as much as a 30% saving on material usage amongst other benefits.

Elematic from Finland, a world leader in the manufacture of precast concrete plants and production lines, recently showcased the benefits of prefabrication in the affordable housing sector at the African Construction and Totally Concrete Expo, at Gallagher Estate in Johannesburg.

Elematic’s Area Director, Curt Lindroth said “Prefabrication in the concrete industry has been around since the 1970s, it offers many positives such as reduced costs, design efficiencies, housing longevity, a reduction in manpower, time and materials as well as greater safety on site. Using local raw materials it offers a faster construction speed as shown by a recent project in India, where using conventional construction methods supplied 15 x 1,000 sq ft. apartments in a month. The prefabricated structure supplied 45 apartments of the same size in the same period of time”.

“At our technical training workshop at the Expo, we highlighted the benefits of prefabrication, particularly in affordable housing projects and how Africa can benefit from this technology.”

Prefabrication needs no shuttering and scaffolding, requires less transportation to site and less materials and equipment.

Prefabricated elements are easily installed with cranes, and offer better quality control and create safer working conditions. No brickwork is needed, less steel is consumed and prefabrication offers a longer building lifespan with less maintenance.

The construction site becomes dry and clean with no curing required at site, which makes water and energy savings achievable. Even in extreme weather conditions no waterproofing is required for the prefabricated structures. A major positive is the simplicity of assembly, which requires the minimum amount of joints.

Precast concrete’s components make it a natural choice in achieving sustainability in new buildings. The structures need no chemical treatment thereby eliminating fumes.

Additionally, it is a solid and secure structure, offering security for occupants as the prefabricated concrete panel is impact resistant and difficult to break or cut through.

Offering corrosion resistant properties, prefabricated concrete is also fire proof, rot proof and rust proof.

Termites, rats, mice and other vermin will not threaten the precast structure, as the components of the precast concrete make it inedible.

Recent Projects Supported with Elematic Technologies

-

Naya Raipur, India – 4,000 housing units

-

Bismayah New City Project, Iraq – 100,000 housing units

-

Arabian Ranches, UAE – 1,041 Villas

For more information, please contact:

Nina Lehtonen

Marketing Manager, Elematic Oyj