AfriSam and Concrete Laser Flooring (CLF) have collaborated successfully in introducing an industry-first environmentally-friendly floor concrete by replacing cement in the mix design with more fly ash, activated slag and admixtures. In typical concrete mix designs, 20% to 30% of the cement is replaced with extenders. In this new concrete, up to 70% can be replaced with the activated slag and fly ash, with the addition of admixtures to achieve superior quality and strength.

“Such development is put through a rigorous research, design and testing process to ensure that our customers can have the benefit of a superior-performing concrete that is also kinder to the environment,” Amit Dawneerangen, National Multi-Product Solutions Manager at AfriSam, says.

“A larger trend within the industry is the move towards ‘greener’ concrete, based on the understanding that producing cement draws on finite resources and that we need to make concrete that uses less cement. There is a growing demand for this from environmentally aware property developers, who are driving the trend for ‘green’ buildings,” Peter Norton, managing director of CLF, says.

With its main focus on new solutions and innovations, AfriSam is also joining forces with CLF in producing low-shrinkage concretes for floors. “Through this speciality design mix, less shrinkage occurs, which significantly reduces cracking in floors. We are currently in the process of researching, designing and testing this product. The goal is to achieve the best performing product, with the lowest shrinkage that also gives our customers the best possible value,” says Dawneerangen.

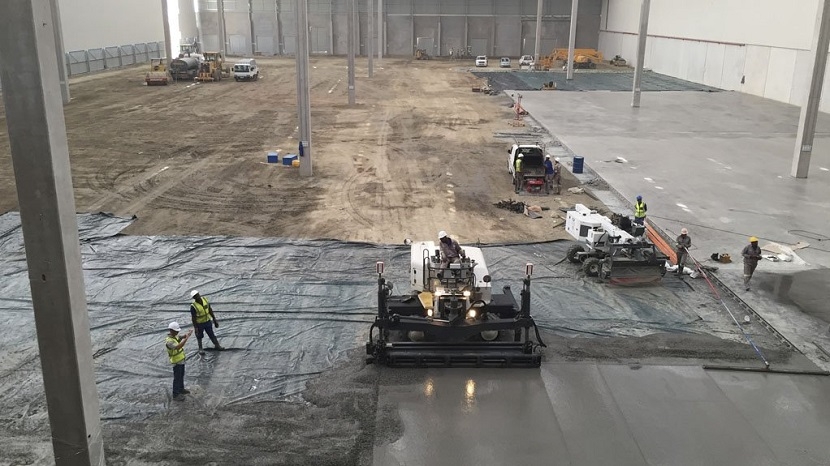

Tilt-up construction is another method the two companies have successfully collaborated on in projects such as a 10,000-m2 building in Pomona. The method utilises the floor of a building as a casting bed for wall panels, which are then simply lifted into position by a crane. Another option is for the wall panels to be cast at a precast yard and then transported to site.

According to Norton, this was a very successful project. “After we cast the floor, we were then requested to cast the walls as well. Such a project would traditionally have used 2,000 m3 of concrete only, but in this instance that figure doubled to 4,000 m3.

“However, the cost of the additional concrete used is offset not only by the dramatic decrease in construction time (which results in significant savings in labour and other input costs) but also by a marked improvement in the quality of the finished structure,” Norton concludes.

More information from Maxine Nel, Tel: +27(0)11 670 5893 / www.afrisam.com